How to Measure a V-Band Flange

If you're looking for a replacement V-Band Clamp or Flange for an existing OEM application please reference the following PDF: V-Band Flange Dimensions.

We know that finding a compatible replacement V-Band Clamp or V-Band Flange for an existing product or application can be quite difficult and one of the most common questions we hear from new and existing customers is, “Why is finding a replacement V-Band component so difficult?” One of the main reasons for the difficulty of finding a compatible V-Band component is due to a lack of “industry standard sizing”, or a lack of an agreed-upon and recognized dimension and sizing standard used by all manufacturers of V-Band components. The result of this lack of standardization can be seen in our very own inventory, as we have three potential V-Band Flange options available for each matching tube size, in the hopes that one will be a potential option for our customer’s application.

The lack of industry-standard sizing has resulted in thousands of OEM and aftermarket automotive and industrial products being introduced to the market that utilize odd and hard-to-find V-Band Clamps and Flanges. Finding a replacement component for an existing product oftentimes turns into a guessing game for aftermarket manufacturers, repair facilities, and end-users who are searching for a compatible Clamp or Flange. In some cases, OEM manufacturers intentionally produce products that utilize proprietary-sized V-Band Clamps and Flanges, with the intention of being the only supplier for the replacement components, which makes finding replacement components both very hard to find and very expensive. We hope that the information provided below will be useful for learning how to measure a V-Band Flange and then find the right matching replacement component.

IMPORTANT MEASUREMENTS TO KNOW AND HOW TO FIND THEM

-

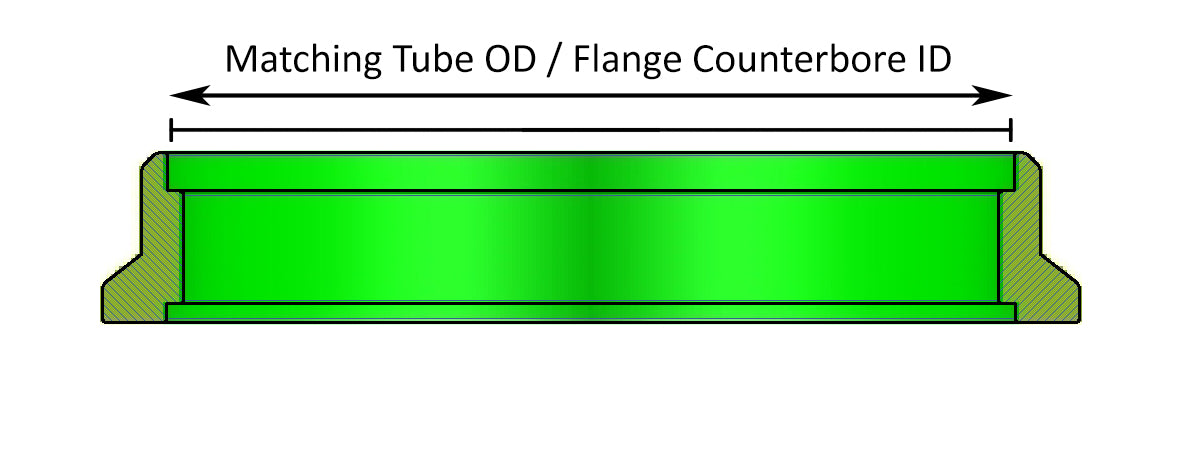

FLANGE COUNTERBORE ID / MATCHING TUBE SIZE OD

Using a measuring tape or caliper, measure the outside diameter (OD) of the matching tube or pipe size that will be welded to the flange. If the tube or pipe is not available, measure the inside diameter (ID) of the counterbore of the weld side of the V-Band Flange.

- OVERALL FLANGE OUTSIDE DIAMETER (OD)

Using calipers, measure across the largest part of the seating surface of the flange to find the “Overall Flange OD”. -

FLANGE APEX WIDTH

Using calipers, measure the Apex Width, or flange edge thickness, of the Flange. Please note, the Apex Width measurement needs to be taken using only the “flat” part of the edge of the flange. When calculating the apex width of a clamp, double the measurement of a single flange.

-

FLANGE BASE WIDTH

Using calipers, measure the Flange Base Width. -

FEMALE RETAINER DIAMETER AND DEPTH

Using calipers, measure the Female Retainer Diameter and Depth. If measuring the Male Flange, measure the diameter and height of the Male ring. If your V-Band Flanges are “flat style” and do not feature a Male/Female Interlocking design please disregard this step. Note, a Female Flange can be combined with a flat style flange if a matching flat style flange is not available.

Once the measurements of your existing V-Band Flange have been taken please consult the following PDF file, V-Band Flange Dimensions, which lists the dimensions of all of our V-Band Clamps and Flanges. If you have any questions regarding V-Band Flange measurements or compatibility please contact us at your convenience: sales@aceraceparts.com

Leave a comment