Pipe vs Tube — Turbo Manifold Material Choices

Fabricating a turbo manifold can be quite challenging, especially if you're doing it for the first time. Aside from the technical challenges of choosing your desired style of manifold, brand of turbo and size, and wastegate placement, the choice between using pipe vs. tube material for your turbo manifold can be quite confusing. What about fabricating your own exhaust system, intercooler piping, or dump tube — how do you know which type of material to choose?

Fabricating a turbo manifold can be quite challenging, especially if you're doing it for the first time. Aside from the technical challenges of choosing your desired style of manifold, brand of turbo and size, and wastegate placement, the choice between using pipe vs. tube material for your turbo manifold can be quite confusing. What about fabricating your own exhaust system, intercooler piping, or dump tube — how do you know which type of material to choose?

"PIPE", "PIPING", "TUBE", "TUBING" ... WHAT IS THE DIFFERENCE?

Often times people use words like "pipe", "piping", "tube", and "tubing" interchangeably and it can get pretty confusing. One area of the fabrication components industry where this terminology can cause some confusion is a term like "intercooler piping". By definition, that is the correct terminology to use; however, if you were looking to fabricate your own intercooler piping and you stumbled across our website, or another website, there might be some confusion during your search for the correct material if you click on the "pipe" category. We strive to make the search for finding the correct material as simple as possible with our website but often times there is confusion between "pipe" and "tube" and which type of material should be used for each job. Generally speaking, in the fabrication components world pipe is used for building turbo manifolds and tube is used for building intercooler piping and exhaust systems.

WHAT IS "PIPE SIZE" MATERIAL?

Pipe size, or Nominal Pipe Size (NPS), is a North American industry designation, or "trade size", that was standardized by the American Standards Association. The use of the word "nominal" in the NPS designation refers to non-specific terms and identifies the diameter of the hole with a non-dimensional number[1]. For example, one of the most common pipe sizes to use when fabrication a turbo manifold is 1-1/2" Schedule 10; however, the approximate outside diameter (OD) of this material is 1.900" and the approximate inside diameter (ID) is 1.682". Based on those dimensions it's easy to see that even though the material is referred to as 1-1/2" pipe there isn't a single dimension that is actually 1.500". Due to the nominal sizing of pipe we never list or reference the material on our website as a decimal (e.g., 1.500") like we do with tube size material.

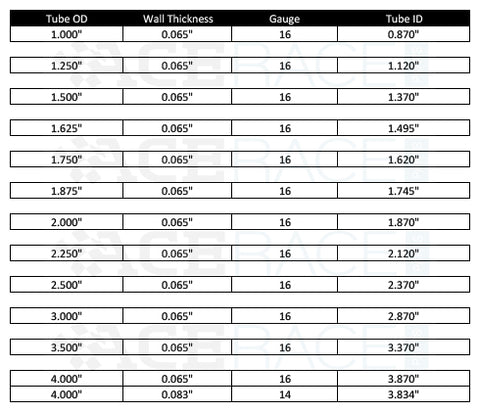

The confusion about pipe size measurements doesn't stop with the mismatch between the named size and the actual size — the wall thickness can also vary in relation to the nominal pipe size. Unlike the wall thickness of tube size material, which is referenced by a gauge that remains constant regardless of the outside diameter, pipe size material refers to the wall thickness as a "schedule" and the thickness will vary depending on the nominal pipe size itself. As you can see from the pipe size chart below, the wall thickness of 1-1/2" Schedule 10 pipe is 0.109", whereas, the wall thickness of 2-1/2" Schedule 10 is 0.120". When referencing pipe sizes from 1/8" to 4", the actual thickness of Schedule 10 material can range between 0.049" and 0.120", as compared to tube size material where 16 gauge is 0.065"[*] regardless of the outside diameter.

The most common pipe size wall thicknesses, or schedules, when building a turbo manifold are Schedules 5, 10, and 40. Although there are many other possible schedules, depending on the nominal size and type of material, these three are the most common when talking about turbo manifolds. The benefits of choosing one over the other is heavily debated and we always leave the decision to use one rather than the other up to the individual fabricator.

WHAT IS "TUBE SIZE" MATERIAL?

Now that we got the hard part out of the way let's talk about an easier subject like tube size material, more commonly referenced as tube or tubing. Tube size measurements are much simpler and easy to understand — the two main components are the outside diameter (OD) and the wall thickness (often referred to as "gauge"). Unlike pipe schedules, tube gauges are constant — for example, 16 gauge is always 0.065"[*], regardless of the outside diameter of the tube. Below is a tube size chart of common proportions used for building headers, downpipes, dump tubes, and exhaust systems. There are many other gauges available for the listed diameters; however, 16 gauge is by far the most common size for diameters 3.500" and smaller. For applications where 4.000" diameter material is used both 14 gauge and 16 gauge are common.

HOW DO I CHOOSE WHICH MATERIAL TO USE FOR MY PROJECT?

We are often asked this question by our customers and due to the number of possible variables there isn't always an easy answer. We do offer a "standard" suggestion to all of our customers when asked pipe vs. tube for their projects:

- If you're building a turbo manifold we almost always suggest using pipe size material. The added thickness of pipe size material, when compared to tube size material, will provide more longevity and be far less prone to cracking. Pipe size material, due to its thickness, is far more robust than tube size material, especially when you hang a 20-40 pound turbo off of the side, heat the material up to incredibly high temperatures, and then add vibration and stress into the equation. Also, most aftermarket head flanges meant for turbo applications are optimized for either 1-1/4" or 1-1/2" pipe size material. It is extremely easy to find a suitable head flange for almost all applications these days and we often suggest, as a baseline, using components that utilize the same size material for the primaries and the head flange.

- If you're building a traditional set of headers for a non-turbo application we almost always suggest using tube size material (including mandrel bends, straight lengths of tube, and either pre-formed merge collector or fabricating your own using a bandsaw and various lengths of straight tube). In the case of building traditional headers for non-turbo applications, the added thickness, and therefore weight, of pipe size material is more detrimental than beneficial.

- If you're building any other component of an exhaust system, including a downpipe, a cat-back, or replacing existing, yet aging exhaust piping we always suggest using tube size material (mandrel bends, straight tube, exhaust flanges and gaskets, etc.). Tube size material is light, yet robust enough to be used for almost every portion of your exhaust system. Also, almost all mufflers, resonators, catalytic converters, and exhaust flanges are based on common tube sizes — using off-the-shelf products to complete your exhaust system is far more cost effective than having to fabricate everything by yourself using non-standard sizes. Lastly, the added weight of pipe size material makes it unsuitable for almost all exhaust applications.

- If you're building your own intercooler piping was always suggest tube size material (mandrel bends, straight tube, v-band assemblies, dual seal clamps, or VanJen assemblies, etc.). Aluminum is by far the most common choice, yet some fabricators choose to use stainless steel material for their intercooler piping.

If you have any questions regarding what type of material to use, or what size material to use, please do not hesitate to contact us.

Comments

Leave a comment